| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

ZHAOQING DEXIN VACUUM EQUIPMENT CO., LTD.

Jindu Industry Zone, Gaoyao, Zhaoqing City, Guangdong / / / CHINA

|

Contact Info: +86 758 851 5892

|

Hall: 11

Stand: 1117 C

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Zhaoqing Dexin Vacuum Equipment Co., LTD., formerly known as Zhaoqing Qianyan Vacuum Equipment Co., LTD. (established in 2009), it is an enterprise specializing in the research and development, production, sales and service of vacuum equipment and glass processing equipment. With dozens of national authorized patents , master the core technology. We take scientific and technological innovation as a means, with the attitude of excellence to provide customers with advanced, intelligent, practical and reliable products. Our equipments have been exported to Poland,Malaysia, Indonesia, India, Iran , Vietnam and other countries.

The silver mirror production line is a chemical spray plating production line. Silver mirror processing process: glass pre-washing, sensitization, silver plating, copper plating, air drying, pre-heating and baking, primer painting, primer drying, top painting, top paint drying, strong wind cooling, mirror washing after plating, air drying. All processes are fully automatic and completed at one time on the production line. Scope of Use: 1、 To produce ordinary silver mirrors (mirror with copper ) 2、To produce copper free and environmental silver mirror 3、To produce corrosion resistant (antioxidant) silver mirror 4、To produce antique mirror

This production line is a chemical spraying production line. The production line mainly consists of automatic loading section, edging section, glass cleaning section, spraying section, glass preheating section, primer drenching section, primer baking section, middle paint drenching section, middle paint baking section, top paint drenching section, top paint baking section, air-cooling section, mirror cleaning section, mark printer, spraying isolation powder machine, automatic unloading section, etc,.it has the advantages of stable quality, energy-saving, and high degree of automation. Scope of use: 1、To produce concentrating plane mirror for solar thermal power station 2、To produce silver-plated mirrors for outdoor use

This production line is a horizontal magnetron sputtering continuous coating production line, mainly composed of washing section, coating section, painting section, baking section, cooling section, mirror washing section, control system, etc, Complete washing, coating, painting, baking, cooling, mirror washing and other processes at one time.and the Ultra-thin aluminum mirror production line, can coat 0.7mm thickness glass. Scope of usage: 1.To produce water-based paint and oil-based paint aluminum mirror 2.To produce aluminium mirrors for construction and decoration purposes 3.To produce dressing mirrors 4.To produce makeup mirrors 5.To produce aluminum mirrors for household products 6.To produce ultra-thin aluminum mirrors

Low-E glass adopt magnetron sputtering method to coat multi-layer metal, compound and medium film on the surface of high-quality float glass substrate. It can prevent radiation of heat from entering indoor and reflect heat of indoor, so that it can reduce the quantity of transmission radiation, possess advantage compare with other energy saving glass

This production line is a horizontal magnetron sputtering continuous coating production line, mainly composed of a washing section, a vacuum coating section, and a painting section. Scope of use: 1.To produce curtain wall glass (Increase the shading effect of the glass and also have the decorative effect of the exterior wall) 2.To produce color mirror (to coat clear glass into various colors glass for decoration and decoration in various place) 3.Can produce tempered glass curtain wall glass/color mirror (first coated and then tempered)

This production line is a horizontal magnetron sputtering continuous coating production line, equipped with a tray return device and multiple pallets. Workpieces with smaller or softer dimensions or a certain degree of curvature can be coated on pallets, while workpieces with larger dimensions and a certain degree of hardness can be transported directly on the shaft roller (without coating on pallet). The tray automatically return back from the bottom of the vacuum chamber, can save the area of the equipment and can reduce labor. Scope of use: 1.Automotive rearview mirror coating 2.Appliance glass coating 3.Plating Electro-Magnetic Interference (EMI)shielding coating on electronic products. 4.Small crystal coating for clothing 5.Acrylic film coating 6.Magnetic material coating 7.Coating for small dimension workpiece or a certain arc workpiece

The coating line is a vertical magnetron sputtering continuous coating line with automatic return system of workpiece frame, which can reduce labor. Scope of use: 1. ITO transparent conductive glass coating 2. Anti-reflection glass coating 1.Electronic product coating(such as mobile phone back cover, etc.) 2.High-grade automobile rearview mirror coating 3.High-grade home appliance glass coating 4.High-grade acrylic film coating

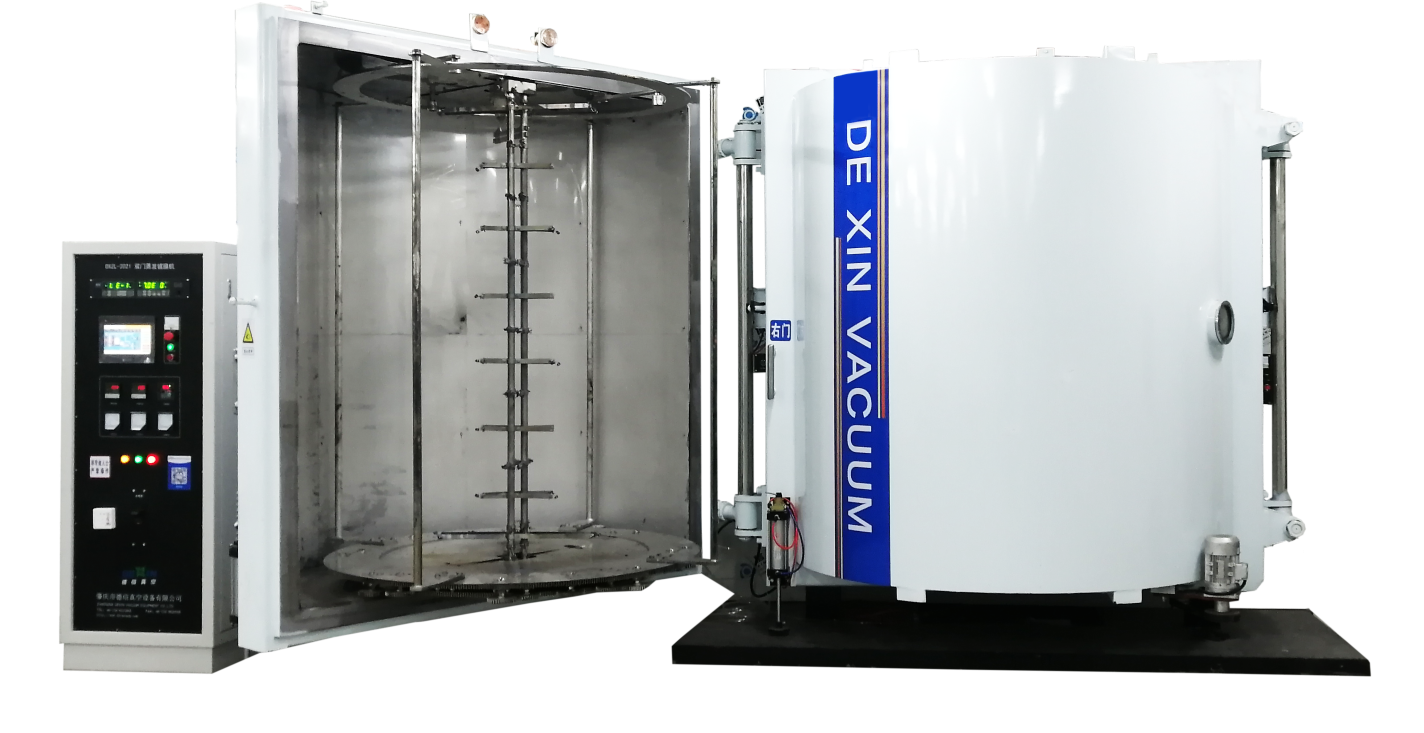

This vertical double door coating machine is magnetron sputtering or resistance evaporation vacuum coating machine. This equipment has unique double door structure, workpiece and coating material loading and unloading is carried out simultaneously with the extraction coating, can effectively improve the work efficiency, increase output and increase economic benefit. Two sets two-door coating units are combined to become one set vertical two-chamber four-door coating machine: the machine shares one set of air pumps and one set of evaporation or sputtering system, which is more energy saving and higher production efficiency. Scope of use: Alcohol packaging products coating, cosmetic bottle caps coating and shoes material coating. Plastic toy coating Acrylic plate coating Automobile wheel hub coating Automotive light coating Car rearview mirror coating Automotive plastic parts coating (Metallize plastics for decorative purposes) Clothing, decoration with crystal, small bead coating

Please visit the company website for more information

Glass washing machine,Painting Machine,Glass bending furnace,Automatic glass loading/unloading machine etc.

No represented companies found.

- TRADEMARK REGİSTRATİON CERTİFİCATE (DEXİN)

TR

TR