| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

HOUSE OF TECHNOLOGICAL SOLUTIONS

92 Konstantin Zaslonov Str., Belgorod / / / RUSSIA (RUSSIAN FED.)

|

Contact Info: +7 908 789-99-68

Web: https://hts.com.ru/

|

Hall: 11

Stand: 1100

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

HTS Manufacturing Company is an engineering manufacturing company that develops, implements and implements integrated technological solutions for water treatment, filtration and purification of water for enterprises in the construction, mining and manufacturing industries. It is located in Russia, the city of Belgorod, Belgorod region. he company has its own production facilities, with a total area of about 1000 sq. m., for the manufacture of integrated water purification systems for industrial enterprises in the field of glass and stone processing, production of reverse osmosis systems for industrial enterprises, automatic stations for the preparation and dosing of technical solutions, as well as filter presses and pumping stations for industrial purposes. The company is also engaged in the design and development of integrated technological solutions, the development of new types of equipment for industrial enterprises, automation of technological processes and the introduction of industrial equipment of its own production into existing production processes. The company was founded in 2018. As a result of the development, the company s specialists have formed their own database of technical solutions, and implemented many projects to improve production processes in Russia and the CIS.

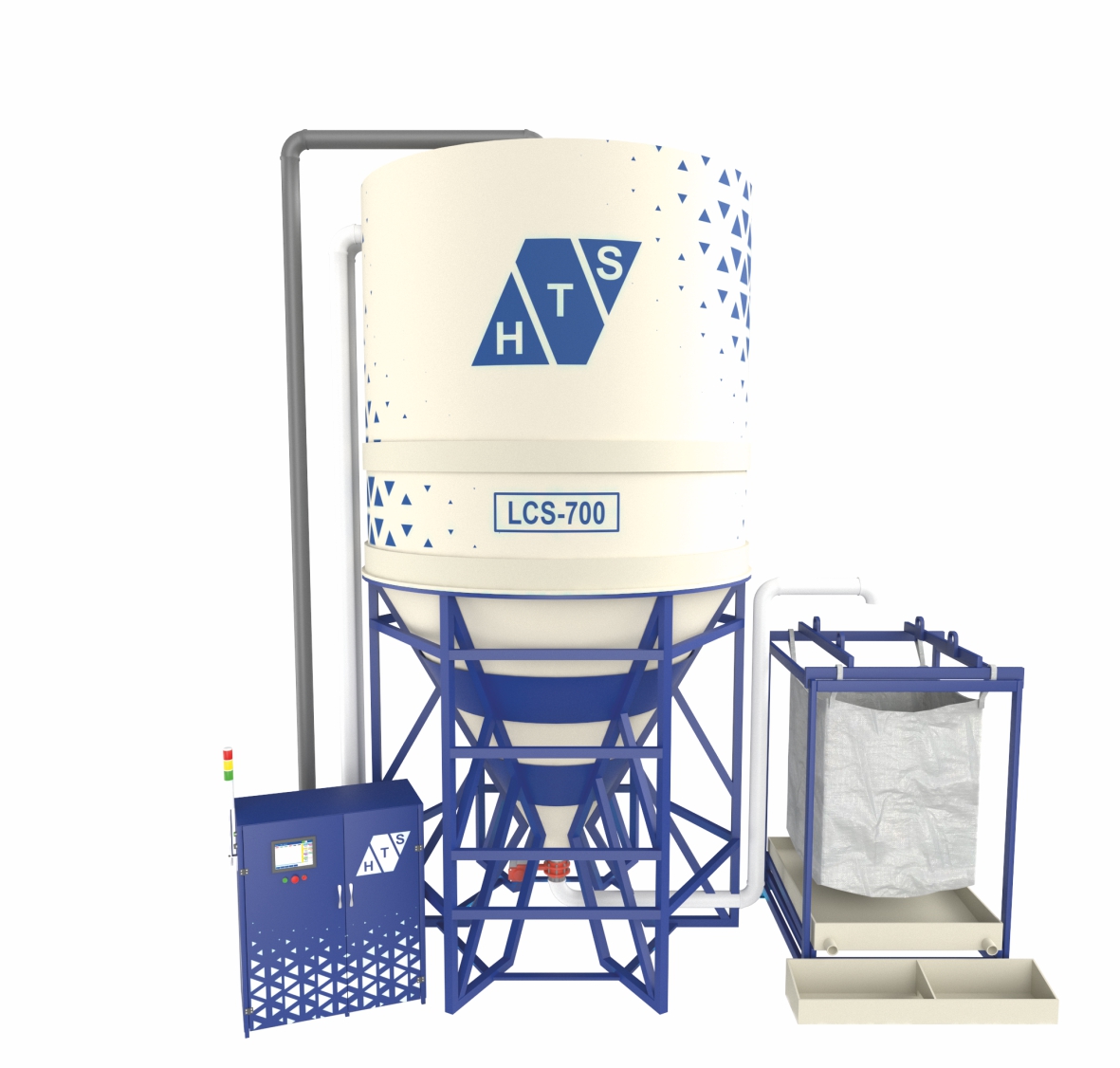

During the mechanical processing of glass and stone, a large amount of sludge is formed, polluting the water used to cool the tool. During cyclic use of contaminated water, sludge clogs the cooling system and equipment mechanisms. To improve the quality of processing and extend the service life of machines, it is necessary to clean the equipment and replace the cooling water quite often with a complete stop of the production process. LCS purification systems are designed for automated water purification in production cycles. Our cleaning systems allow you to minimize equipment downtime, increase production efficiency, improve the quality of products, and save time. 1. Minimize production downtime, increasing the profits of enterprises. 2. Save effort, time and money for machine maintenance, sludge collection and disposal. 3. Increase the service life of machine tools and machining tools. 4. Reduce the load on the sewerage system, reduce the cost of its maintenance. 5. Improve the quality of glass and stone processing. 6. Minimize product defects.

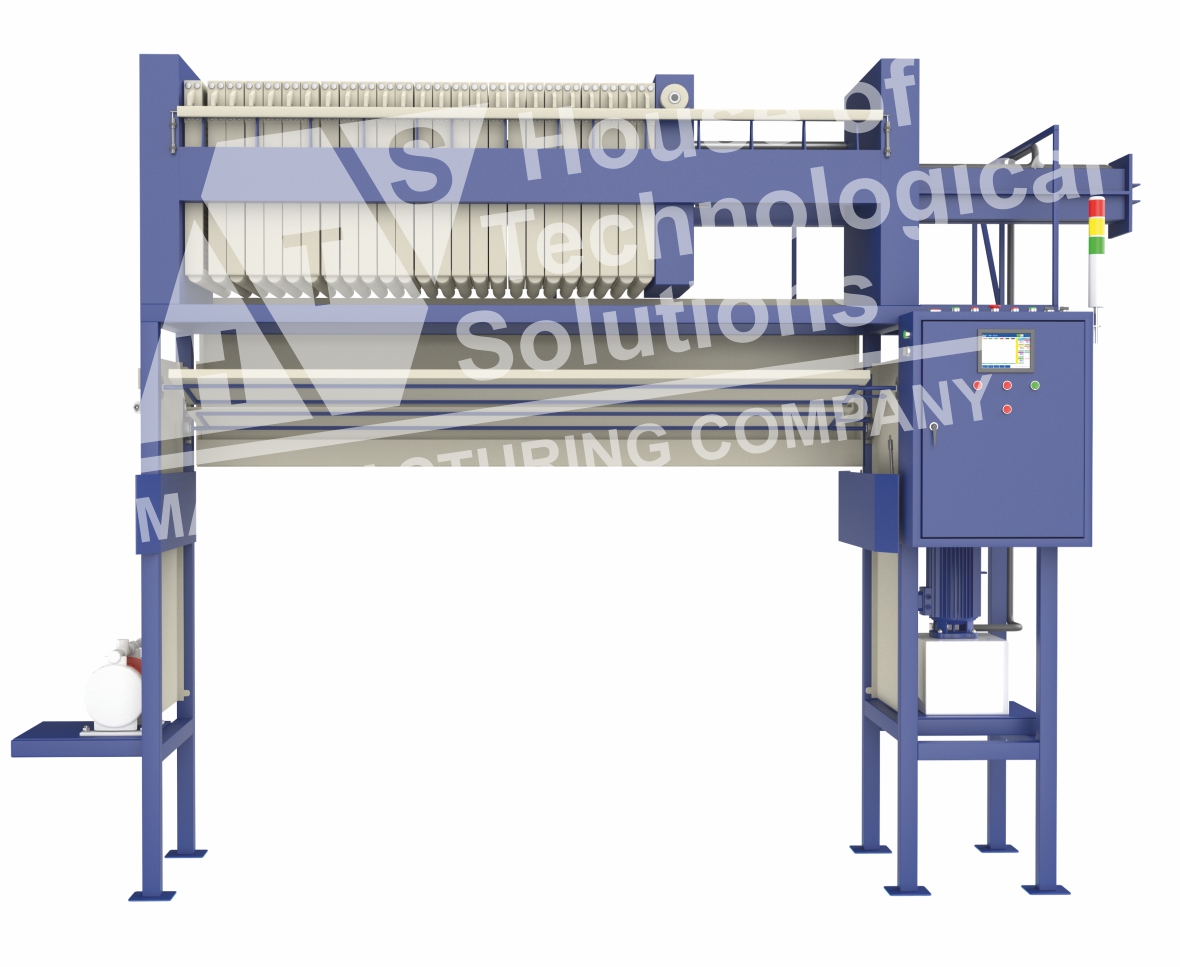

THE LOW HUMIDITY OF THE SLUDGE (SLUDGE) Filter presses can provide a sludge moisture content of up to 10%. REDUCTION OF SLUDGE TRANSPORTATION COSTS Drier sediment is more convenient and cheaper to transport for disposal. COMPACT SIZE WITH HIGH FILTRATION AREA Due to the possibility of choosing the optimal size and number of plates, filter presses have a sufficiently large filtration area, which allows sludge dewatering even at large wastewater treatment plants. MODULARITY OF THE DESIGN The filter presses have a modular design, which makes it easy to change the performance of the equipment depending on the needs of the enterprise. THE POSSIBILITY OF AUTOMATION Filter presses can be fully automated, which reduces labor costs and increases productivity. The supporting frame of the filter press is made of steel Electrohydraulic station Slurry pump for filter press Filter Plate Package Homogenizer tank for sludge collection Drip tray Automatic plate shaking system Automatic control cabinet Automatic protective shield of the drop zone

It is intended for water supply with maintenance of working pressure. Fully automated pumping stations. the sphere of public water supply; increasing the pressure of tanks and pressure pipelines; municipal, industrial, industrial and private applications; residential and office buildings, hotels; pumping of drinking, industrial or cooling water. The capacity, working pressure, and pumping equipment are selected individually depending on the customer s requirements. The reverse osmosis system is designed for deep purification and desalination of water, removal of organic compounds, microorganisms, suspensions, for the preparation of domestic, industrial and drinking water. Main and backup pump with electric drive on the frame Control cabinet Common frame, racks, pipelines, cranes (gate valves) Membrane hydraulic tank Control and measuring equipment Pressure switch with dry running protection Dry running protection device Check valve

No represented companies found.

- HOUSE OF TECHNOLOGİCAL SOLUTİONS

- HTS

TR

TR