| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

JINAN BOKE GLASS MACHINE CO., LTD.

Chengdong Industrial Park, Shuangshan Street Office, Zhangqiu District, Jinan City, Shandong Province, 250000 / ZHANGQIU / JINAN / CHINA

|

Contact Info: +86 53188528189

|

Hall: 12A

Stand: 1269 B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Jinan Boke Glass Machine Co.,Ltd was built at the outset on July 12, 2000. It is a new high-tech private enterprise integrated production, scientific research, development the insulating equipment of middle and high-grade. Till 2019 April, we have produced and sold more than 4500 IG production lines. Boke is one of leading manufacturers with famous brand, perfect quality and good after-sale service in China. We are TOP 3 brand in China. Before its set up, our founder Mr. Wang Zhengsheng and his brother have had more than 10 years experience in the field of insulating glass production. Till now we have more than 20 years experience in IG line field. Through ISO9001 Quality Management System, High tech and quality through the most up-to-date fabrication methods distinguish us as one of global market leaders. Our machines have attained CE Certificate and several patent rights. From 2017, we export all our insulating glass production line through our export company Shandong XY International Trade Co., Ltd, which is invested by Boke. XY is the only partner and exporter of Boke.

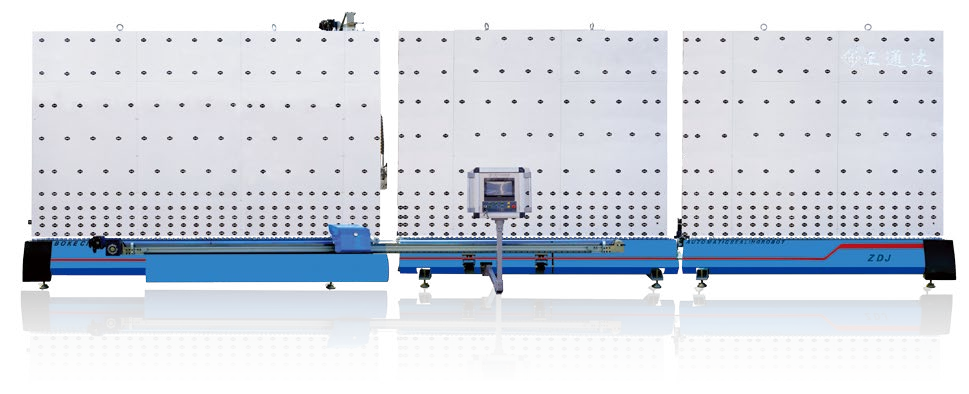

This Vertical Insulating glass machine is composed of 1)loading section, 2)washing and drying section, 3)Transmission and storage section 4)aluminum spacer bar positioning section, 5)Outer penal assembly and transmission section 6)IGU assembly and inert gas filling section, 7)transmission, storage and unloading section. With special design, it can wash Low-E glass effectively with high speed. This line is controlled by PLC and realizes the automatic control and frequency control of the motor speed of the whole line. It adopts advanced assembly technique and solves the problems of uneven press and misplacement of the glass. The assembly section adopts limit switch and cylinder tank whose travel distance can be adjusted, making the operation easy and the location precise and the movement reliable. There are two operation methods in the control panel automatic and manual . If the separate operation of each section or maintenance is needed, the manual operation method is needed. A.Three pair of brushes import from USA, DuPont brand. Which is well known for its fine quality and durable in use. They can wash Low-E glass. Duont 610 food grade brushes with 0.06mm~0.08mm bristles, effectively remove static electricity. B. Automatically distinguish the coating side of coated glass and Low-E glass. C.Adopt waterproof bearing without oil lubricant, SKF brand import from Sweden. D. The washing body adopt stainless steel and anti-rusting materials. E.The PLC and other electric elements adopt Siemens brand, import from Germany. F.With automatic inert gas filling function in the press section. The inert gas filling efficiency is more than 90%

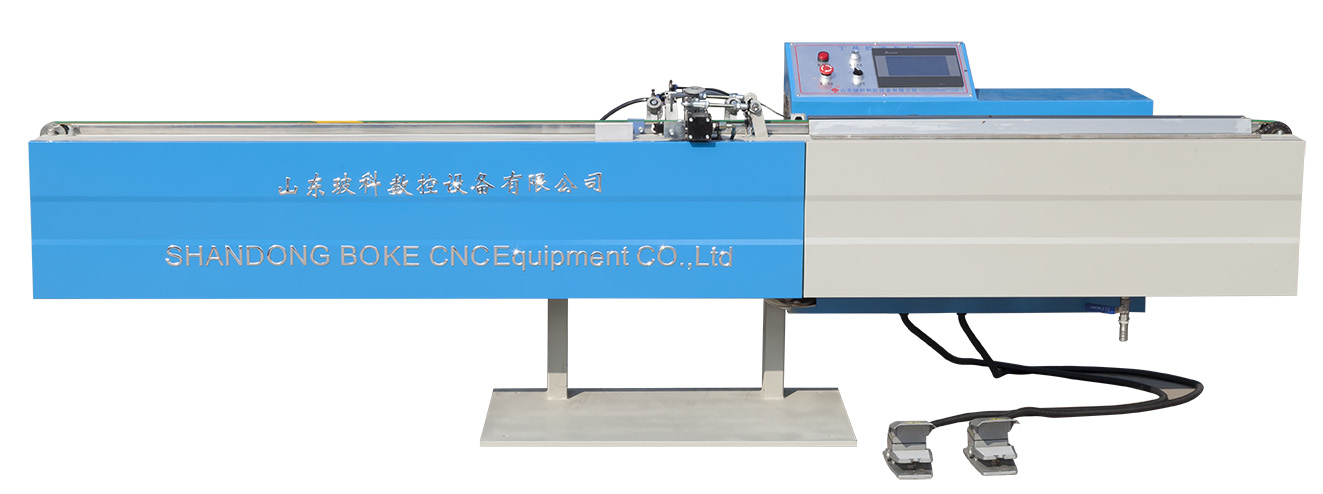

1) Gluing part adopts special relocation mechanism, ensure the gluing nozzle will touch IG unit closely, but will not break it. And it can adapt to a certain range of displacement error of IG unit. 2) Sealing width is adjustable by inputting parameter, convenient and accurate. Sealing depth can be detected automatically. The sealing speed is controlled by sealing depth and gluing quantity, ensures the sealing quality. Adding glue on the IG unit corner, ensures the sealing quantity on the corner. 3) All important electric elements, adopt imported famous brand products, such as Servo motor, controller, low-voltage apparatus, sensors, fiber optic photo switches and so on. Which will make sure the equipment runs well, reliable and long service life. 4) Sucker, reducer, rails, sliders and other key moving parts are adopted from foreign brand, to ensure a smooth transfer of glass, safe and reliable. 5) Hydraulic glue, through pressure on the hydraulic station to meet the quantitative oil supply of the driving oil cylinder, so as to control the white glue for quantitative glue. And ensure the black glue quantitative glue through the mechanical linkage adjustment ratio. It is easy to use, simple and reliable. 6) ZDJ-V25 Automatic sealing robot adopts the combination transfer mode of a high quality precision 3 rows of roller chain and a unique V block. The roller is connected with the processing surface of the cross beam, low friction force, high effect, stably running of the coated glass, which ensures the good spreading effect. 7) Adopts Touch screen man-machine interface, graphic combination, convenient to understand and easy to operate. 8) Automatic digital control system by servo motor ensures the equipment precision and glue precision. The system also has a unilateral sealing, alarming, dangerous to be automatic determination and lock function. 9) This equipment can work alone, or equipped with IG unit production line. The later condition can develop more efficiency. 10) This robot adopts high quality Aosong board through the NC machining and wheel combination, beautiful and durable. 11) By optimizing the structure, this robot achieves low power consumption and high efficiency.

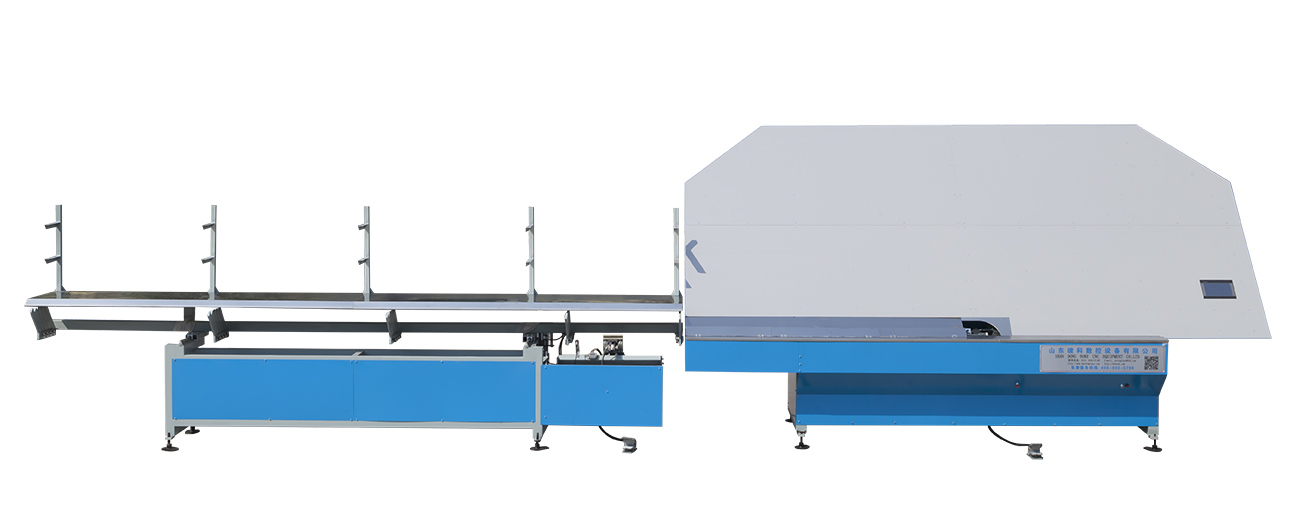

1) Adopt PLC control system and touch human-machine interface. Multi-screen clear and technical parameter simply input. 2) Feeding material and bending aluminum spacer by servo motor guarantees the precision of the bending form (angle and arc). 3) Aluminum frame have smooth arc, which is beautiful after butyl coating. 4) Bending aluminum frame and theoretical size error is less than 1mm, high speed, high efficiency. 5) Can feed four different size of aluminum spacer with four store tanks. 6) Automatic avoid spacer joint when bending and cutting spacer. 7) Can do shaped aluminum frame.

1) Adopt PLC control system and touch human-machine interface. 2) Can fill bendable and non-bendable aluminum frame. 3) Adjust filling height according to the various sizes of the aluminum frame. 4) High filling speed by drilling holes in the back. 5) Seal the filling holes automatically. 6) Monitoring the quantity of desiccant and replenish material automatically.

The machine is special equipment for coating two sides of aluminum spacer and has many advantages such as evenly coating glue, large amount of extruding glue, high production efficiency, adjusting the space between the two glue nozzles automatically, convenient operation and maintenance and high automation etc. 1. Adopts stainless steel hairline board, which has neat and beautiful appearance. 2. Four variable frequency speed control. 3. The glue tanker diameter 200mm, which is suitable for all kinds of butyl. 4. The glue jar warning system will work when the butyl is used up. 5. Timing boot for 24 hours, save preheat time. 6. Adopt touch screen man-machine interface, easy to operate, high degree of automation. 7. PLC control system. 8. It is convenient to adjust the distance between glue nozzle automatically.

No represented companies found.

- BOKE

TR

TR